The construction industry is undergoing a robot revolution, but how are we supposed to adapt? Get an inside look at some of the new robotic technology breaking into the industry today! From 3D printing to demolition, these robots can do it all.

What kind of Robots are out there?

3D Printing Robot

3D printing robots are not necessarily a new topic of conversation. It was way back in 2004 that the first 3D printed wall was created by a University of South Carolina Professor, Behrokh Khoshnevis. Now it’s possible to print entire houses in less than a day! With more companies realising the potential of 3D printing the 3D printing market is expected to grow to over $56m by 2021.

What 3D Printing Robots are in the industry today?

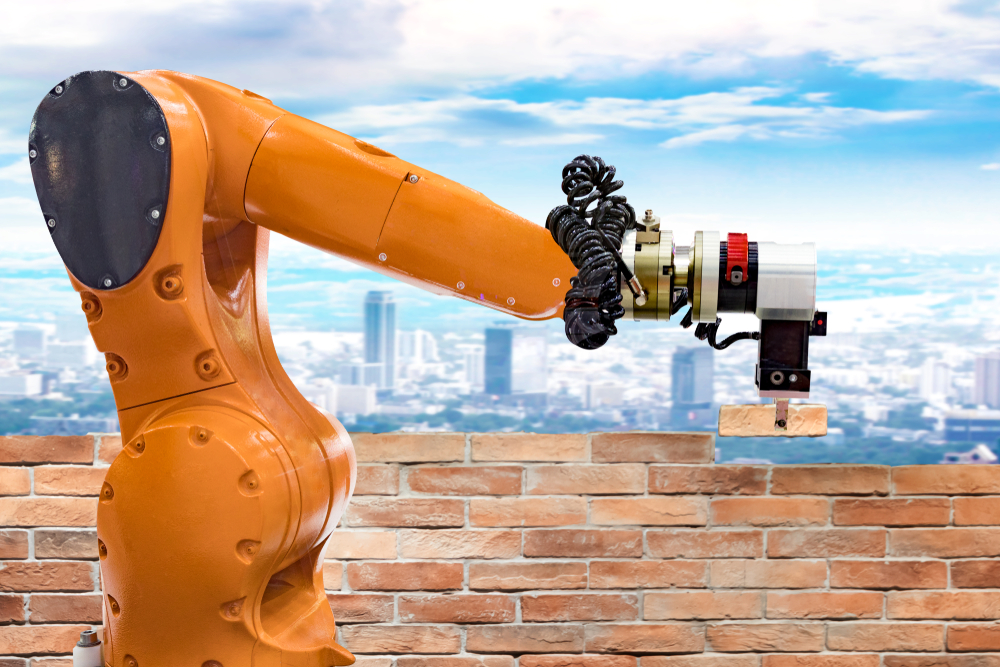

Robotic Arm – These are used in The Contour Crafting method of construction. This involves the material being deposited and manipulated to create a large 3D structure that’s smooth to the touch. Rails to support the robotic arm are installed all around the construction site so the arm can move exactly where it needs to be.

Sand Layering – Italian architect Enrico Dini, best known for his 3D printed houses, demonstrated his latest project using a D shaped 3D printer. This new machine works by binding powder into a solid layer of material with a binder. This works by depositing layers and layers of sand before the printer pours out the droplets and the binder hardens it.

Metal for Solid Structures – A Dutch Company named MX3D have developed a construction method called WAAM or wire arc additive manufacturing which enables the user to 3D print metal structures using a 6-axis robot that can drop about 2 kilos of material per hour.

What can 3D Printing Robots do for YOUR Business?

- Reduce Costs

- Reduce Waste

- Faster Construction

- Reduce Accidents

Bricklaying Robot

SAM 100 is a brick laying robot that can work up to five times faster than the average construction worker. SAM stands for “Semi-Automated Mason” and can reportedly place between 300 and 400 bricks an hour. When compared to a human that typically lays around 60 to 75 bricks an hour that’s an incredible improvement. Not only with SAM save you time but it will save your workers the backache of bending over form hours on end and could even potentially save you from the severe labor shortage plaguing the industry the past few years.

What are some of the Benefits of SAM 100?

- Designed to collaboratively work with human mason

- 50%+ labor savings

- Increase productivity

- Lower safety risks for your workers

- Improved job planning

Demolition Robots

The Husqvarna DXR is a series of remote-controlled demolition robots. You read that right, remote controlled demolition robots. You can now control big powerful machines from a safe distance away. These robots are typically used when a job is too challenging or time consuming for human workers to do it efficiently.

Benefits of Automating the Construction Industry

The construction industry is arguably one of the least automated industries in the market, but why is that? What are the benefits of automating the construction industry? While construction tasks are notorious for being difficult to automate, robots excel at tedious, repetitive tasks so the worker can focus on the parts of the project that take more focus and attention to detail.

Top 3 Benefits of Automating the Construction Industry

- Save time, money, resources, and effort put into projects

- Reduce the risk of potential injury for your workers

- Better quality of work

When comparing human built walls to that walls created by these automated machines, it’s easy to see that with the level of complexity increasing with each project, automating the process could quickly pay off.

Some people over at the AEC or architecture, engineering, and construction industry, can no longer ignore the benefits that construction could reap if the industry used these robots more frequently. They see the benefits in Dubai as well, regulations are said to require every building to be constructed from at least 25% 3D printed materials and sources by the year 2025.