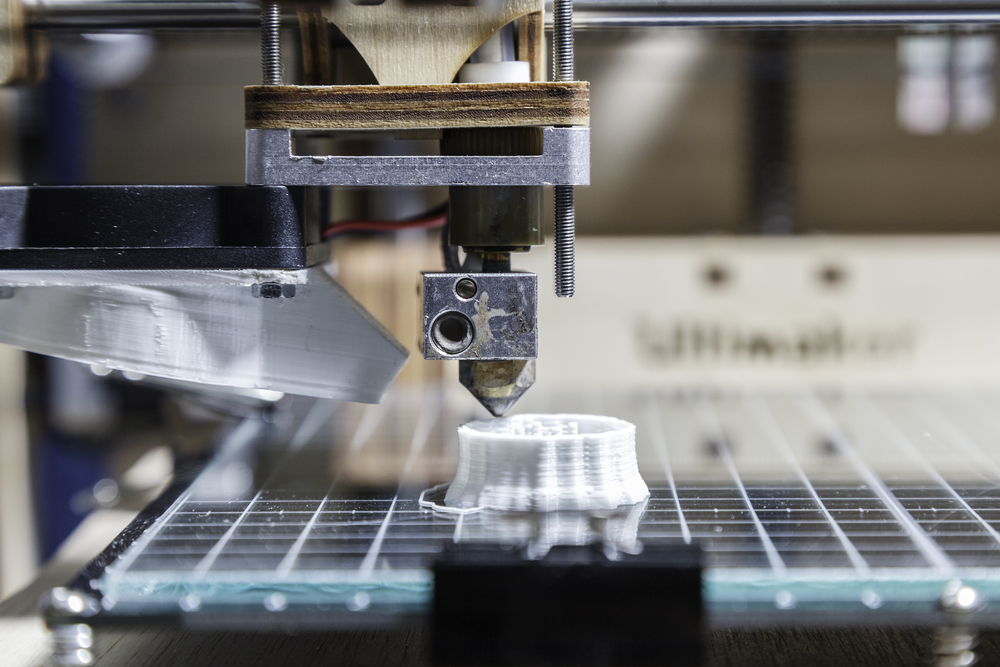

3D printing has slowly been growing in popularity over the past few years, most recently making its imprint on the construction industry, making it a major part of the fourth industrial revolution. Most 3D printing technology in the construction industry uses concrete as the main building material but Zoubeir Lafhaj, an engineering school graduate from Ecole Centrale de Lille, in France, is absolutely certain that concrete, is not the future of 3D printing.

“3D printing is a formidable tool to introduce robotisation into into construction, and other kinds of innovation,” Zoubeir Lafhaj, an expert in the future of construction explained, “It will also help to tackle environmental issues such as reducing waste.”

According to Lafhaj, we should be moving towards more materials that use less energy and produce less waste while having a lower carbon footprint. Lafhaj goes on to explain how plastic is a good alternative to concrete. Not only is it more environmentally friendly but in dense urban areas like Tokyo Japan, it can be much easier and cheaper to import into the city and move around the streets.

“In some areas in Japan there are not a lot of streets where you can construct new buildings,” Lafhaj says, “they need new materials that can be brought in without big machines.”

3D printed bioplastics can already be seen being used on construction sites around the world. On a canal-side site of Dus Architecture in Amsterdam they’re already using the bioplastic to build tiny 3D printed houses.

“We have entire 3D printed tiny houses, all kinds of staircases and walls standing here,” sayd Hedwig Heinsman, the co-founder of the company, “it looks like a modern-day ruin.”

Heinsman went on to explain the major advantages of this type of construction, the small amount of waste produced during the construction process. “On an average building projects you have about 25% material waste,” she says, “with printing we really do only use the material that we actually need.”

3D printing could be the future of construction. Environmentally friendly, less waste created, and can use a multitude of different building materials like plastic and bio-based plastics made from food waste like broccoli, lemons, and almond shells.